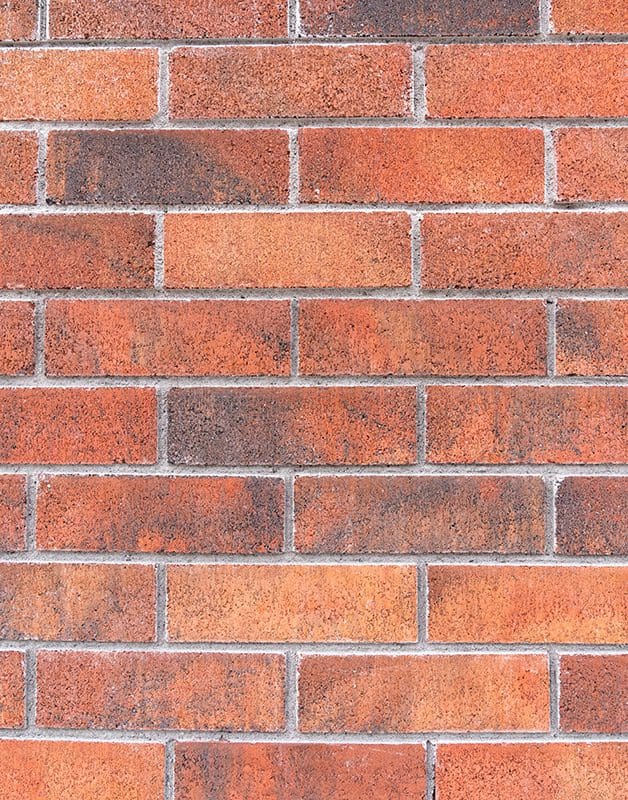

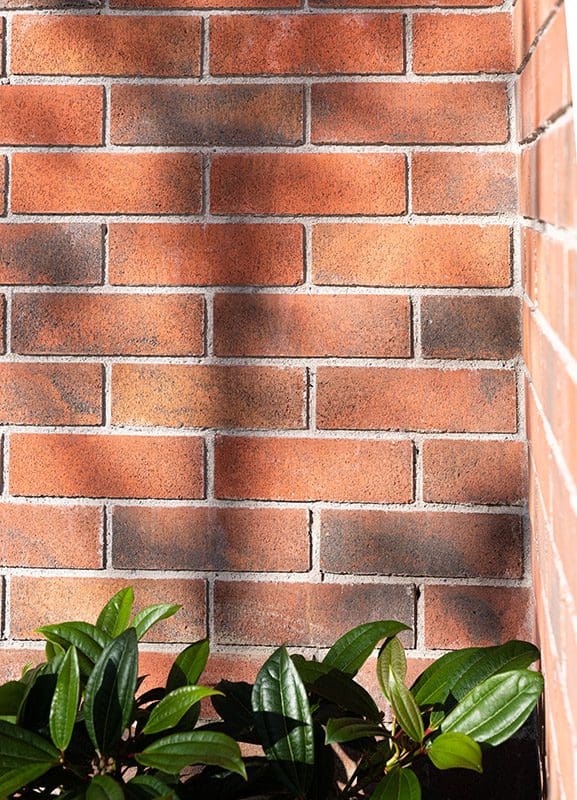

Woodward Brick

Frogged brick in two distinct finishes

Better Buildability

Introducing Woodward Brick, a modern facing brick designed specifically for improved buildability and stability. Our new Woodward collection is available in two finishes. The ‘Smooth’ finish is vibrant with a smooth, sharp crispness; while the ‘Antique’ finish is rumbled with mellow pastels in the reclaimed style.

Woodward is designed with a hollow depression on the top face – commonly known as a frog – which reduces the weight of the brick, thus making it easier to handle.

Available Colours

Hampton Smooth

Hampton Antique

Tullamore Smooth

Tullamore Antique

Edenmore Smooth

Edenmore Antique

Oldtown Multi Smooth

Oldtown Multi Antique

Lyndhurst Smooth

Lyndhurst Antique

Shandon Smooth

Shandon Antique

Durrow Cream Smooth new

Durrow Cream Antique new

Ashbrooke Smooth

Ashbrooke Antique

Vintage White Smooth new

Vintage White Antique new

Olde Dublin Buff Smooth new

Olde Dublin Buff Antique new

Wicklow Smooth new

Wicklow Antique new

Lewis Smooth

Lewis Antique

Doonmore Smooth

Doonmore Antique

Clarendon Blue Smooth

Clarendon Blue Antique

The Benefits of AG Woodward Concrete Facing Brick

We visited a house building site recently to see AG concrete facing brick in works. We asked the Brick Layers what they think of using concrete facing brick when compared to traditional materials and dispelled some myths in the process.

Description

A frogged brick in two distinct finishes - smooth and antique

Sizes

215 x 102.5 x 65mm

More Information

Minimum order quantities are required for certain sizes, depths, colours, etc. Before placing an order, please speak to one of our sales teams – they’ll be happy to advise on this and any other product questions you may have.

You can reach them on:

UK: 0121 747 0202 | Ireland: +44 (0)28 8778 8112

One day, all bricks will be made this way.

Introducing Woodward Fine Cast Brick – now with Enduur 1. Discover the improvements and benefits of our Fine Cast Brick range and the introduction of Enduur 1 to the Woodward Collection.

NBS Product Specifications

- Full Spec Info

- Create your own specifications

- Integrated with NBS Chorus

NBS Source

NBS SourceCase Studies

Featuring Woodward Brick

Downloads

View all downloads relating to Woodward Brick

Do you have a technical enquiry about this product? Use the short form below and someone will be in touch.

Request a sample for this product to see it in the flesh.

Get a quote for this product & we will get in touch as soon as possible.

Why AG Professional?

Superior Quality

At AG we pride ourselves on superior quality and exceeding our customers’ expectations. Product quality is continuously being monitored and improved to provide the best quality products for our customers.

Expert Knowledge

The AG team have a wealth of experience and knowledge to share with our customers and clients. Our Technical Department is here to help – we pride ourselves in providing an unmatched level of support to make sure that all our customers get the best advice and the best possible solution for their projects.

Unrivalled Support

At AG we believe in unrivalled support and will closely monitor and support every process from design concepts and specifications to fully indemnified engineered designs. From product supply and installation, to delivering samples, site meetings and technical support, AG will be with you on this journey.

Easy Spec

We offer a fast and easy specification service with our Sales and Specification department on hand to help with any queries. We have partnered with NBS Source which provides key specification information at your fingertips in platforms such as RIBA Product Selector and NBS Chorus. This delivers relevant product information, literature, case studies and certificates to our clients at a more effective level.

Availability / Delivery

Our team from our sales department to our despatch office work closely with customers to create a dedicated call off plan for your project. Detailed delivery planning will be scheduled around clients’ needs to ensure we provide the best customer service.

Sustainable Approach

AG have a strong commitment to the link between a sustainable environment and our local Community. In line with our Corporate Social Responsibility Strategy AG defines sustainability as the intrinsic balance between the social, economic and environmental aspects of our business operations. We have established a Net Zero Carbon team with the aim of reducing carbon emissions and are committed to producing low carbon products in our strategy.